To: Mr. O

From: Adam Kincaid

Date: 06/05/16

Subject: Proposal for a new class.

Introduction:

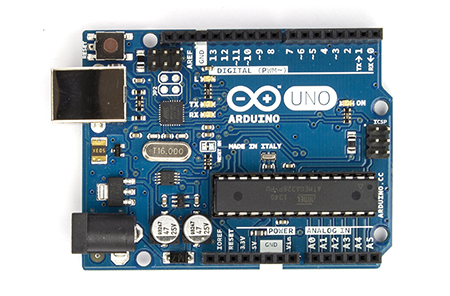

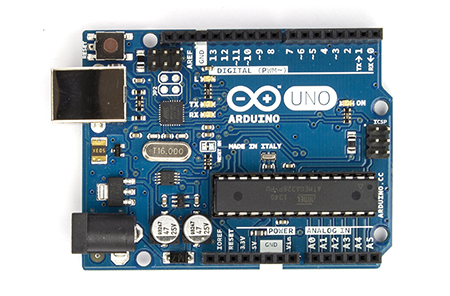

I have an idea for a new class for 10-16-year-old youth at the community center. We should start an introduction to Arduino class. Arduino is a micro-controller used for prototyping and hobby level circuit design. In this class, students would learn the basics of circuit design and basic programming in a variant of the C programming language. This would give us another technology class and would give us a serious technology class as opposed to a recreational technology class.

Image: Arduino Uno, Source: arduino.cc

Background:

We have only one technology class at the community center. If we are truly trying to reach as many youths as possible, we are failing miserably when it comes to the technology fields. The closest class we have to a technology class is a single Lego robotics class. We have plenty of outdoors classes, sports classes, and art classes but when it comes to technology classes Lego robotics is the only one. I believe that we are losing a large chunk of the community because we don’t offer classes that interest them.

This class would allow us to introduce youth to circuit design and programming as well as help increase interest and knowledge in these fields. It could increase interest enough to help promote the study of electronics and programming to a level that more technology companies move into the area to take advantage of the new potential workforce. This could lead to bettering the economic status of the area. We do what we can at the community center to better the community. What we have here is a chance to potentially help stimulate the local economy as well as ensure our youth don’t get left behind the technology curve due to a lack of finances.

Benefits and Feasibility:

As mentioned before this class should help raise interest in technology as well as potentially help the local economy a few years down the road. Other benefits include,

- A new technology class

- More diversification in classes

- Potential for class off-shoots such as;

- programming in a more professional language

- digital electronics

- analog electronics

- higher level Arduino classes

- potential partnerships with local technology companies

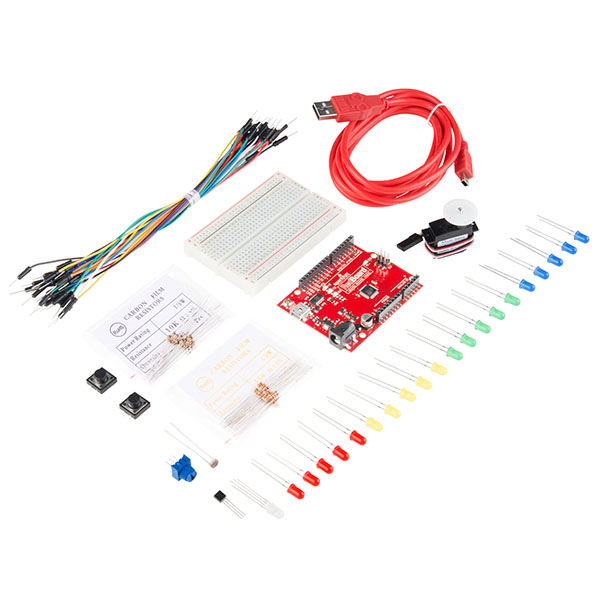

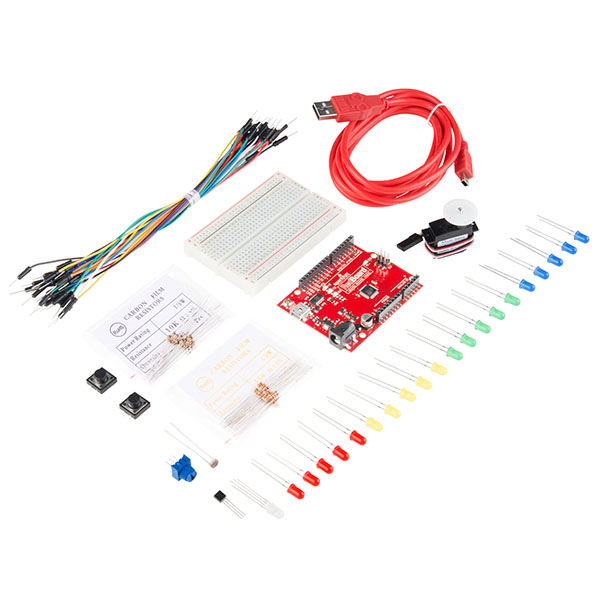

As far as feasibility goes this class is potentially very feasible. Arduino kits can be as cheap as $50 and if we get some for use at the barn and that we keep class to class the price for each term should remain low. There is a potential issue with replacing resistors, capacitors, microchips, LEDs, and wires. These won’t need to be replaced every class and could be stocked up on over time to keep the cost down. There are lots of resources online available for planning and background information.

Method:

The class will be in session once a week for five weeks with a class time of 1.5-2 hours. each class will have a main project that we focus on and try to achieve in the time allotted. If a youth finishes their project for the day early they would be allowed to experiment with what they have already learned or accept a challenge from the instructor. I have laid out an idea of what each class would focus on below.

Week 1: We will focus on the basics of circuit design and programming. we will do this through some lecturing to cover the basics and then work on a simple program to turn on and off an LED at different speeds.

Week 2: We will look at push buttons and how they can be used to effect variables in our programs.

Week 3: We will expand our knowledge of variables and how we can manipulate them by using a potentiometer. We will also learn about programming libraries and how to use them by using a servo motor.

Week 4: We will learn how to use a temperature sensor and how the serial monitor can be used.

Week 5: We will use all of our knowledge to build a temperature monitoring point that will have a green LED on until a certain temperature is hit. Once we reach the desired temperature a red LED will turn on, the green LED will turn off, and a servo motor will trigger to simulate a vent opening. After the temperature falls below a specified point the servo motor will reset and the red LED will turn off and the green LED will come back on.

Schedule:

This class should not take long to set up. Once we have the materials the only thing we would need to do is train any assistant teachers we may need and get the class added to the recreation guide. Below I have an outline of how long I think we will need subject to change depending on funds and when the next recreation guide is coming out.

June 20th: Kits and extra parts ordered.

June 24th-29th: Kits and extra parts received and sorted.

June 30th-July 9th: Assistant teacher training, most of this will consist of the assistant teacher working through the curriculum themselves based upon the main teachers guidance along with internet resources. It would be preferable that most of the guidance the assistant teacher receives is from the internet. This is preferable because it will hopefully yield new ways of doing the tasks.

Week of July 11th: First day of the new class. Actual day depends on the availability of the art loft.

Week of August 8th: Last day of class.

Qualifications:

My experience that qualifies me to put together this class as well as teach it is,

- An associates degree in electronic technology

- classes included

- Micro-controllers

- Programmable Logic Controllers 1-3

- PLCs are similar to micro-controllers but are used for more industrial purposes.

- Digital electronics 1-2

- Semiconductors 1-3

- Experience teaching Lego Robotics classes

- 1-year being an assistant teacher

- 1-year being head teacher

In the micro-controller class, I used an Arduino kit and became proficient at programming and designing circuits for it. I did projects ranging from turning on an LED to creating a theremin controlled by two light sensitive resistors. PLCs gave me an idea of how different control systems work. this could be useful because I can give the youth an idea of how what they are doing in class is similar to what happens in industry.

Cost and required resources:

Below is a list of projected cost for this class. It excludes the purchase of computers because we already have those at the community center. All of these items are from Sparkfun because they are a trustworthy source for Arduino products and parts. I have included some spare parts on this list that I believe it would be good to have. In the future, we may have to order parts not included on this list. This list should hold us over for two sessions at least and possibly even more. the life span of some of the components is going to be entirely based on how well the youth listen and pay attention to how things are supposed to be installed. Due to that being the largest factor in component lifespan it is difficult to say how long we will have before we have to do a resupply order.

Image: Proposed Arduino kit, Source Sparkfun

Conclusion:

If we do start an introduction to Arduino class we will be able to round out our offered classes and cater to a section of youth we don’t currently cater to. This could raise interest in some of our other classes as well as lead to classes related to Arduino like introduction to programming, introduction to analog circuits, and introduction to digital circuits. We currently have one class related to technology and starting this class would be a very good way to begin to serve that part of the community and could lead to more classes in this area of interest. It has a fairly low initial cost and could have a low operating cost and the possibility to pay for itself in enrollment fees very quickly. If you have any questions, concerns, or want to talk more in depth with me about this feel free to email or call me.